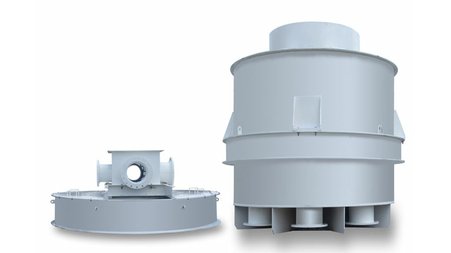

Tube Conveyors

These tube conveyors will be used to transport limestone and gypsum.

Somerset Welding & Steel (SWS) was contracted by Lincoln Contracting & Equipment (LCE), to manufacture large diameter tube conveyors for conveying limestone and gypsum.

- Large steel tubes: 26’ – 40’ lengths, 8’ – 14’ diameters

- Qualified submerged arc welding process

- X-ray quality welding

- Adjustable fixtures for superior tolerance and repeatability

- Large capacity shot blast and paint facilities

- Capable of meeting stringent quality requirements